In today’s world, where technology is advancing every day, 3D printing has revolutionized the manufacturing industry. It allows users to transform digital designs into physical objects, making the process of prototyping and production more efficient and cost-effective. At FASIVE, we offer high-quality 3D printing services to help businesses and individuals bring their ideas to life.

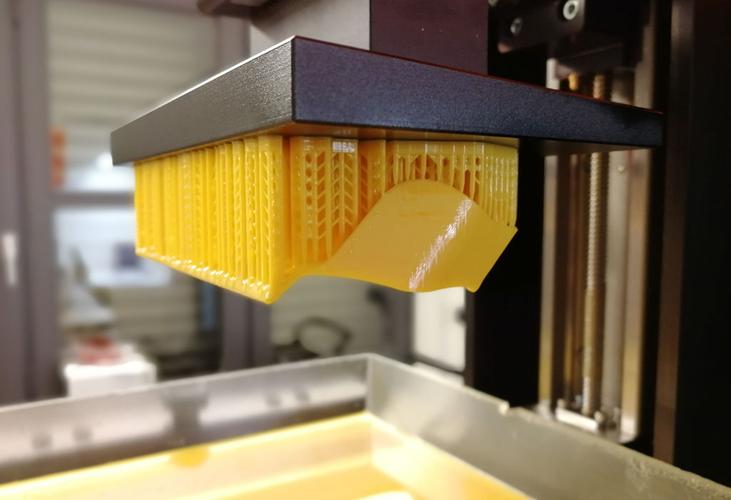

3D printing is a form of additive manufacturing that uses a layer-by-layer approach to create a three-dimensional object from a digital model. Unlike traditional manufacturing processes that involve cutting or drilling away material, 3D printing adds material layer by layer until the final product is complete. This allows for more complex and intricate designs to be produced with greater accuracy and efficiency.

Rapid Prototyping: 3D printing allows for rapid prototyping, which means that a physical model can be created quickly and easily from a digital design. This can significantly reduce the time and cost involved in developing a prototype, enabling businesses to bring their products to market faster.

Customization: With 3D printing, customization is easy and affordable. Each object can be customized to meet the specific needs of the user, allowing for greater flexibility and creativity in design.

Cost-Effective: 3D printing can be more cost-effective than traditional manufacturing methods. Since it requires less material and produces less waste, it can significantly reduce production costs.

Complex Designs: 3D printing allows for the creation of complex and intricate designs that would be difficult or impossible to produce with traditional manufacturing methods.

Product Design: 3D printing is commonly used in product design to create prototypes and test new designs before manufacturing begins.

Medical Industry: 3D printing is also used in the medical industry to create custom implants and prosthetics, as well as for surgical planning and training.

Architecture: Architects and builders use 3D printing to create models and prototypes of buildings and structures, allowing for a better understanding of the design and potential issues.

Education: 3D printing is also being used in education to teach students about design and engineering concepts and to encourage creativity and problem-solving skills.

At FASIVE, we believe that 3D printing has the power to revolutionize the manufacturing industry. It offers numerous benefits such as rapid prototyping, customization, cost-effectiveness, and the ability to create complex designs.

In today’s world, where technology is advancing every day, 3D printing has revolutionized the manufacturing industry. It allows users to transform digital designs into physical objects, making the process of prototyping and production more efficient and cost-effective. At FASIVE, we offer high-quality 3D printing services to help businesses and individuals bring their ideas to life.

3D printing is a form of additive manufacturing that uses a layer-by-layer approach to create a three-dimensional object from a digital model. Unlike traditional manufacturing processes that involve cutting or drilling away material, 3D printing adds material layer by layer until the final product is complete. This allows for more complex and intricate designs to be produced with greater accuracy and efficiency.

Rapid Prototyping: 3D printing allows for rapid prototyping, which means that a physical model can be created quickly and easily from a digital design. This can significantly reduce the time and cost involved in developing a prototype, enabling businesses to bring their products to market faster.

Customization: With 3D printing, customization is easy and affordable. Each object can be customized to meet the specific needs of the user, allowing for greater flexibility and creativity in design.

Cost-Effective: 3D printing can be more cost-effective than traditional manufacturing methods. Since it requires less material and produces less waste, it can significantly reduce production costs.

Complex Designs: 3D printing allows for the creation of complex and intricate designs that would be difficult or impossible to produce with traditional manufacturing methods.

Product Design: 3D printing is commonly used in product design to create prototypes and test new designs before manufacturing begins.

Medical Industry: 3D printing is also used in the medical industry to create custom implants and prosthetics, as well as for surgical planning and training.

Architecture: Architects and builders use 3D printing to create models and prototypes of buildings and structures, allowing for a better understanding of the design and potential issues.

Education: 3D printing is also being used in education to teach students about design and engineering concepts and to encourage creativity and problem-solving skills.

At FASIVE, we believe that 3D printing has the power to revolutionize the manufacturing industry. It offers numerous benefits such as rapid prototyping, customization, cost-effectiveness, and the ability to create complex designs.